Project Objective: From Theory to Reality

While theoretical knowledge is crucial, this project was conceived to bridge the gap between academic concepts and real-world application. The primary goal was to undertake the complete mechanical and electrical conversion of a conventional car to a battery-electric platform. This involved tackling complex challenges in powertrain design, weight distribution, battery management, and high-voltage safety, providing invaluable hands-on engineering experience.

My Role: Lead Mechanical & Electrical Integrator

As the lead engineer on this conversion, I was responsible for the entire project lifecycle, from initial design to final road testing. This hands-on role required a multidisciplinary skill set:

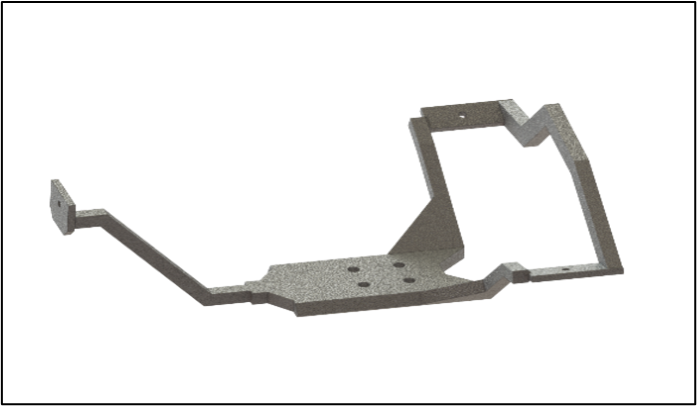

- Mechanical Design & CAD: Designing custom mounting brackets for the electric motor and battery boxes in SolidWorks to ensure structural integrity and proper weight distribution.

- Component Sourcing & Selection: Researching and selecting all critical powertrain components, including the AC induction motor, motor controller, and Li-ion battery packs with an integrated Battery Management System (BMS).

- Fabrication & Assembly: Executing the physical conversion, which involved removing the original engine, exhaust, and fuel systems, followed by welding, fitting, and installing the new electric drivetrain components.

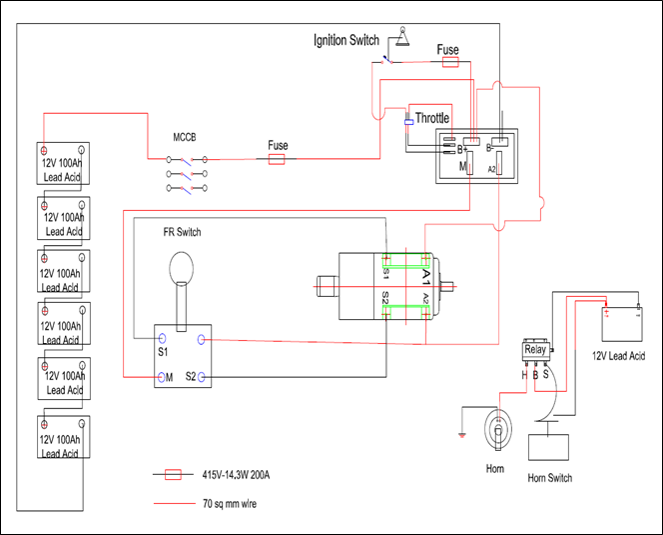

- Electrical System Integration: Designing and implementing the complete high-voltage and low-voltage wiring harnesses, connecting the battery packs, controller, motor, charger, and auxiliary systems.

- Testing & Validation: Performing rigorous safety checks and initial road tests to validate the vehicle's performance, range, and thermal management.

Technical Approach: The Conversion Process

The conversion was a multi-stage process, demanding careful planning and execution at each step to ensure a safe and reliable outcome.

1. Design & Powertrain Mounting

The first critical step was to design a robust adapter plate and motor mount to couple the new electric motor to the car's existing manual transmission. Using SolidWorks, I designed a mount that utilized original engine mounting points to minimize chassis modification, ensuring optimal alignment and strength.

2. Battery System Fabrication & Installation

Safety and weight balance were paramount. I designed and fabricated battery boxes to house the 12, placing them strategically in the front and rear of the vehicle to approximate the original weight distribution. These boxes were integrated with the all-important Battery Management System (BMS) for cell monitoring and protection.

3. High-Voltage System Integration & Testing

With all major components in place, the final stage was the meticulous integration of the high-voltage electrical system. This involved wiring the motor controller, DC-DC converter, onboard charger, and contactors. Each connection was carefully routed and insulated, followed by rigorous testing protocols to ensure all safety systems were operational before the first test drive.

Conclusion & Key Outcomes

The project successfully culminated in a fully operational, road-legal electric vehicle, serving as a powerful proof-of-concept for sustainable transportation alternatives. This complex undertaking was an unparalleled learning experience, solidifying both theoretical knowledge and practical engineering skills.

- Functional Prototype: Transformed a gasoline-powered car into a zero-emissions electric vehicle capable of daily driving.

- Hands-on Skill Development: Gained extensive practical experience in CAD, mechanical fabrication (welding/fitting), high-voltage electrical system design, and project management.

- Deep Systems Understanding: Developed a holistic understanding of EV architecture, from the battery-motor interaction to the challenges of thermal management and component integration.

- Problem-Solving Expertise: Overcame numerous unforeseen mechanical and electrical challenges, reinforcing adaptable and creative problem-solving abilities.